|

Listen to this article

|

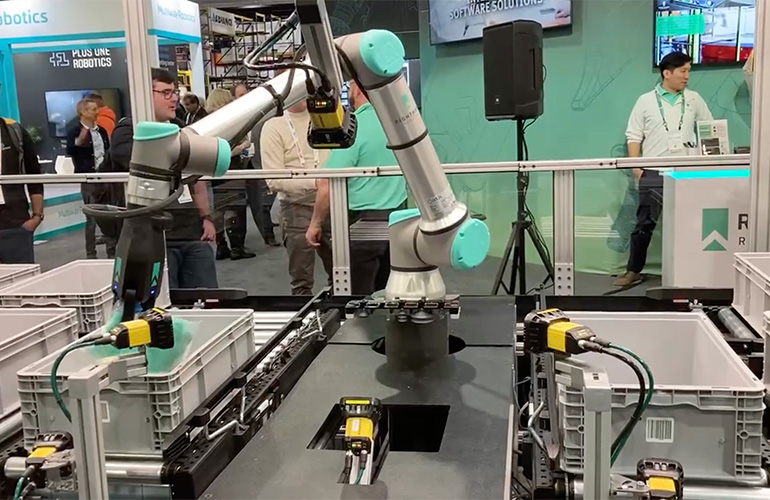

RightHand Robotics Inc. has hit the ground running in 2024. Earlier this year, it released RightPick 4, an upgraded version of its piece-picking system that can handle items up to 25% larger and 50% heavier than RightPick 3.

The Charlestown, Mass.-based company worked closely with integration partner Vanderlande on many of the new features in RightPick 4. The companies’ close partnership is key to both successful deployments and future technology development, according to David Schwebel, head of sales and strategic business development at RightHand, and Jake Heldenberg, North American head of solution design for warehousing at Vanderlande.

The Robot Report caught up with Schwebel, Heldenberg, and Paul Eyre, RightHand’s director of channel sales, at MODEX last week. They shared insights on industry trends, RightPick’s latest capabilities, and more.

End users approach robotics differently this year

So, how has the show been for you?

Schwebel: This is probably the best-attended MODEX ever, and it’s actually even better than ProMAT last year.

What we’re hearing is that we’ve gone past moments of inspiration and education. We’re in the engagement phase. Quite often, the people that are coming by are saying, “I already trust what I see. I’ve seen the Vanderlande SIR system. I wanted to see the new features and things that you’re doing at RightHand. Now how can I engage further?”

We’re seeing great experiences and great collaborations. So, now it’s all about taking their information, understanding their workflows, and finding the right individuals to bring it across to you.

They sold more than 44,000 rooms in Atlanta this year, which was about 25% larger than it was at MODEX two years ago. And with all that, they’re expecting more than 50,000 to 56,000 people to walk through the halls.

Eyre: I’m just coming up for air to be honest, which is great. What I’m seeing in my conversations is that customers are now expressing a level of trust in the technology. They’re moving from exploration into engagement with the technology, and they really want to start adopting the technology.

I think they’re also starting to get into the technology, so they can maybe instruct their integrators that “These are the types of technologies we’d like to use and we’d like you to adopt.” So, now they’re becoming far more educated and involved in the decision-making process rather than leaving that to integration partners.

And that’s great for us because they come to us, and we’re able to generate leads and give them to our integrators first. I’ve had conversation after conversation with end users saying, “OK, it’s time to do this. Now show me where this has been installed previously. Show me how I can employ these technologies effectively in my solution.”

Schwebel: We’re often hearing that customers held back on investments over the past three years, and they’re finally at a place where they have to refresh their existing environments.

So, between the availability of the capital, the interest, and the engagement, we’re experiencing trust with the product. They see it’s de-risked. They see going through the integrator environment is absolutely the right thing to do. And they’re replicating what they did about seven to 10 years ago. So, we’re in that great crux of “It’s time to engage and engage fast.”

While Vanderlande doesn’t have a booth, how has it been being all over the show?

Heldenberg: The funny thing is, I’ve actually had more engagement this year without a booth. A lot of times, you bring in your current customers or customers you’re already working with.

Walking the show has been really interesting. The questions I’m getting are more specific, and people are saying, “Hey, I’m ready to invest.”

Last year, it was very exploratory. People came here trying to figure out all these new technologies, what’s going to benefit them. And now, each time I run into a customer it’s like, “Hey, we’re ready. We need to move.”

So it has been a very interesting change and shift for me also, just being able to walk and see all the new technologies. If we had a booth, I wouldn’t have a lot of time to walk around. I’ve been able to go take a look at all the different new technologies — some more exciting than others, to be pretty blunt about it.

What has been some of the more exciting stuff?

Heldenberg: We’ve seen autonomous crane robots, or ACRs, come along, and the AMR [autonomous mobile robot] technology has come up. I see that when it comes to flexibility.

ACR isn’t going to wow you [throughput-wise] yet against a shuttle system. But on a low-capacity system, [it offers] flexibility and the lack of a single point of failure. I see that is really the next technology that’s going to take off as far as ASRS [automated storage and retrieval systems] goes. That’s what I’ve been most impressed by. In years past, you’d see it, and it’d still look a little clunky, there were still stability issues. All of that is getting resolved.

Item-picking issues we saw last year are already getting resolved. So this year, even with RightHand, the new gripper is a lot better and a lot more advanced. All these new technologies that have sprung up over the past five years are becoming more stable and more robust. And for me, I see nothing but opportunity, especially for the customers.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

What potential customers are looking for

When these customers approach you, what kinds of metrics are they really interested in hitting?

Eyre: For me, it’s throughput, throughput, throughput when it comes to robotics. They’re interested in whether the technology available today can match or exceed the performance of a human. I’m not saying that’s always the case, but the technology is improving to a level where it’s coming up to those levels of matching human performance.

This makes things very, very interesting for them, because it addresses the issues of labor availability and retention, which are causing a lot of heartburn. It’s becoming acute in a lot of geographies.

Heldenberg: Five years ago, the technology and vision systems were not quite where they needed to be. Like 50% of SKUs were inaccessible. But now, that we’ve seen more things, especially when it comes to small boxes or odd-shaped items, can be picked successfully.

The system can prove it can be consistent over a 16-hour shift. So, the business case is clearly there. A robot doesn’t take a break. It doesn’t need to go to the bathroom.

So what we’re seeing as a level of investment now is people saying, “I want to buy one or two or three of these bots. Let’s put them in and have stations that are prepped and ready because once we prove it on those first few booths, I want them into half of the stations.” So performance is important, but it’s also performance that’s sustained through an entire shift.

Eyre: The range has increased substantially. Picking a large range reliably really lends itself to an increase in autonomy. That means a lack of intervention or reduction of human intervention to resolve exceptions within the robot station is increasing and improving substantially year over year.

You need very, very few humans to support a fleet of robots. So autonomy is something that you have to have KPIs [key performance indicators] for earlier on, and something they’re measuring is the level of human intervention or autonomy.

RightHand shows off RightPick 4 at MODEX

What are some of the improvements in RightPick 4, and has RightHand Robotics gotten a lot of interest in it?

Schwebel: So, effectively through collaboration through both our system integrators coming into our roadmap and some work that we did with Staples, we packaged that all together into a full released product.

This newly released platform allows us to handle items that are 50% heavier, so up to 3 kg or 7.2 lb. without a problem. The range of items that we’re able to handle [has grown]. Now, we’re able to do polybags and apparel. This allows us to handle more than 70% of all the different types of items available in omni-retail and e-commerce.

We’re able to expand the size and range of the setup. The new type of cameras that we have allow us to have a greater environment space to work in. So, if I wanted to have more open borders at the same site at the same time, we could. It’s more frictionless for the system integrators. It literally is an idea where you can have it arrive on-site and four hours later, it’s installed.

We asked Vanderlande to join our booth, where we want to show a consistent workflow loop among multiple stations for its customers, from multipack detection to suction-cup swapping, as well as industrial cameras and spacing. We’re hardening our technologies to make them frictionless for customers.

Can you give some insights about RightPick 4 from the integrator side of things?

Heldenberg: So, as far as RightPick 4, we’re excited about it, that’s what I can say. One of the greatest things about working with RightHand in particular is that when we come to RightHand with a challenge, they really step up.

We have fashion customers, and ultimately they were challenging us and saying, “Hey, we need to automate more. We need to figure out how we can improve productivity, we have labor challenges, and we can’t hire enough people, especially during peak season.’

And so we challenged RightHand point-blank and said, “Hey, this is a challenge for us, and we haven’t found anyone who can really successfully complete the task of automating fashion item picking.”

We also came back with bisected totes, and RightHand immediately began working on the problem. We’re looking at unique ways to pair item picking with new technologies and adaptive sequences. For ASRS, software must be able to split orders, sending some to manual stations.

Ultimately, RightHand stepped up to the plate, and you can see a lot of innovation in RightPick 4 and also in the software and vision system improvements across the board. So now we are much more comfortable going into these fashion customers.

With RightPick 4 and a lot of the innovation, we appreciate it because we know it comes from the challenges that we and many others bring to RightHand. And that’s where I saw RightPick 4 is a great example of all of those challenges culminating together into a good solution.

Tell Us What You Think!