|

Listen to this article

|

MassRobotics Executive Director Tom Ryden introduces Locus Robotics at RoboXchange. Credit: Eugene Demaitre

BOSTON — MassRobotics last night hosted the first in its RoboXchange series of events intended to encourage collaboration among academia, startups, industry, and global partners around robotics and artificial intelligence. It included presentations by Opteran and Locus Robotics spanning research and development to use cases for mobile robots and software.

MassRobotics started RoboXchange in accordance with its mission to help the Massachusetts and global robotics ecosystems through informative and networking events, said Tom Ryden, executive director of the nonprofit. With its sponsors and partners, MassRobotics also provides workspace and other resources for startups, as well as support for STEM (science, technology, engineering, and mathematics) educational programs.

Editor’s note: MassRobotics is a strategic partner of WTWH Media, which produces The Robot Report and the Robotics Summit & Expo.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

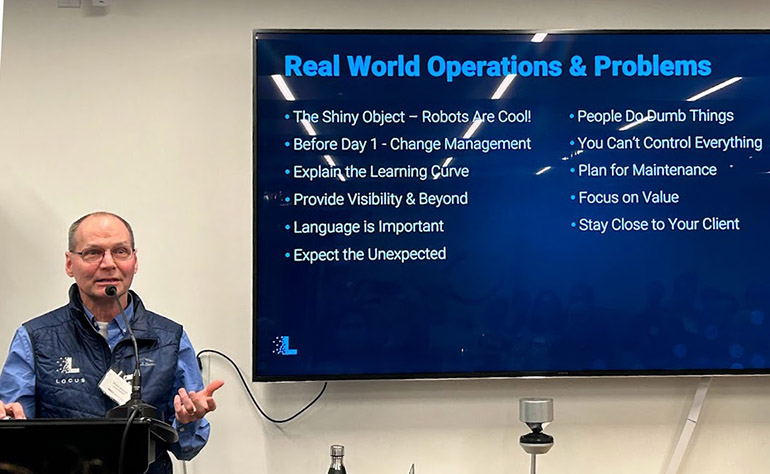

Warehouses should expect the unexpected, says Locus

While warehouses are increasingly adopting autonomous mobile robots (AMRs), unexpected challenges can still derail deployments, noted Steve Branch, vice president of sales engineering at Locus Robotics. The Wilmington, Mass.-based company has produced over 13,000 robots that have collaboratively picked more than 2 billion units at more than 280 facilities in 18 countries.

Ten percent of Locus’ customer sites have more than 100 robots, its largest has an area of 1.2 million sq. ft. (111,000 sq. m), and the biggest deployment included more than 800 robots at peak, Branch said. Customers include third-party logistics providers (3PLs), retailers and e-commerce companies, and healthcare firms, he added.

Not everyone welcomes robots at first, Branch acknowledged. There have been instances of vandalism, “mostly from the uninformed or the older generation,” he said. “But we’ve been surprised at how quickly the user base adopts the technology once it realizes how robots can make their jobs easier.”

“Robots are cool,” said Branch. Since the COVID-19 pandemic, Locus’ clients have become its best promoters, and warehouse associates increasingly realize that AMRs can help extend their careers and offer new opportunities as “robot wranglers,” he said.

Surprises can include environmental challenges, such as changing lighting conditions or dust covering sensors. They can prompt redesigns.

“People do dumb things, like blocking banks of chargers overnight,” said Branch. In addition, users might overload AMRs, add unapproved accessories such as bungee cords, or change throughput for “buy one, get one free” promotions without taking systems into account, he said.

“You can’t control everything, and warehouses already struggle with changing numbers of operators,” Branch observed.

Locus Robotics’ Steve Branch discusses automation challenges at RoboXchange. Credit: Eugene Demaitre

Locus shares tips at RoboXchange

Branch explained that there are ways to prepare for unpredictable problems, including setting expectations, adopting change management best practices like go-live readiness teams, and increasing visibility into processes. Locus Robotics‘ robots-as-a-service (RaaS) model also helps with maintenance and support, according to Branch. It is based on monthly fees, with typical contracts covering three years, he said.

Robotics developers and vendors should focus on demonstrating value at scale to chief financial officers, Branch advised. “We want customers to reach their goals in 60 days,” he said. “Locus has a savings calculator to help before big deployments.”

By visiting clients and soliciting feedback, Locus got pulled into the European market and added the heavy-duty Vector from its Waypoint acquisition to its Origin AMR lineup, he recalled.

In response to questions at RoboXchange, Branch said that Locus supports efforts to make AMRs work across brands and with other equipment. They include the MassRobotics AMR Interoperability Standard. “We’re getting more requests to work with robot arms and workcells for picking and autonomous loading/unloading,” he said.

“We also work with warehouse management systems,” Branch said. “We see ourselves as a software or total solution company, not just a robotics company.”

Opteran looks to insects for new AI model for robots

Conventional machine learning models are based on decades-old understandings of the human visual cortex, asserted Prof. James Marshall. The researcher at the University of Sheffield and chief scientific officer of Opteran presented on “How to Build a Robot Mind” at RoboXchange

“An estimated $75 billion was spent on autonomous vehicles by 2022, and the Apollo program cost $260 billion, adjusted for inflation,” he told attendees. “Imagine if that had been spent on really understanding how intelligence works.”

“Current AI algorithms copy the brain’s spiky processing, but that’s likely a product of how our wetware conserves energy,” Marshall said. “Current navigation such as SLAM, or simultaneous localization and mapping, is data-intensive, compute-heavy, and dependent on network connections.”

Animal brains evolved to solve for motion first, not points in space, he said. Marshall cited examples including the sea squirt, an invertebrate that digests its own brain once it’s no longer needed for its mobile phase of life.

“The fruit fly has only 100,000 neurons, and its brain’s ellipsoid body can still solve navigation and motion,” explained Marshall. “A honeybee with less than 1 million neurons can fly out miles, return to its hive, and communicate where it found flowers as well as conduct other behaviors.”

Other models based on the neural network of C. elegans, or fruit fly, don’t provide the “navigational richness” that Opteran is aiming for, he added. Marshall co-authored a peer-reviewed research paper on “Insect-inspired AI for autonomous robots.”

Opteran’s Prof. James Marshall discusses a new bio-inspired approach to AI at RoboXchange. Credit: Eugene Demaitre

Opteran shows new navigation approach at RoboXchange

Opteran said it has reverse-engineered information-processing principles for a small development kit that works with cheap sensors. The U.K. company provides vision and perception that it claimed is “orders of magnitude” more robust than more deterministic AI. In fact, it doesn’t require plath planning and can dynamically avoid objects, said Marshall.

“We provide I/O for collision prediction and robust output for panoramic, stabilized 3D visualization,” he said.

“To share the technology now, we’ve productized Opteran Mind 4.1,” said Jack Pearson, commercial director at Opteran. “It solves for localization at lower cost than SLAM.”

In a live demonstration at RoboXchange, Opteran’s team showed how a robot could use its technology to autonomously navigate a course lined with mirrors and changing lights — normally a problem for SLAM.

“We’re working toward safety certifications and cognizant engines and are on a journey to build decision engines,” said Marshall.

Tell Us What You Think!