|

Listen to this article

|

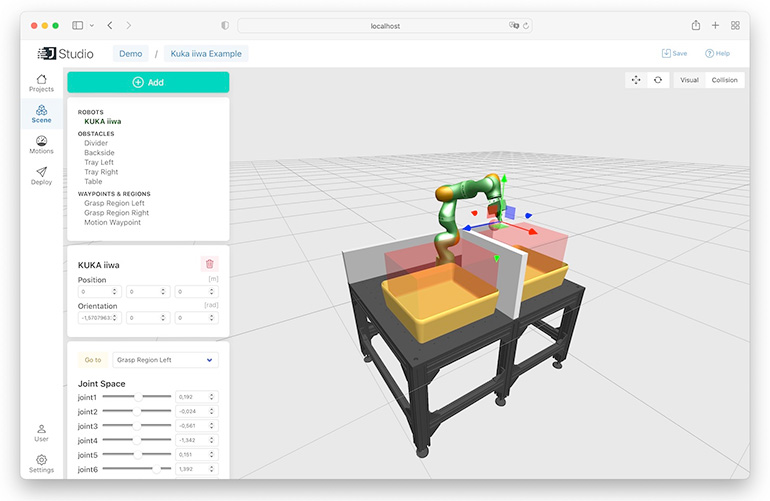

Jacobi Studio is a web app designed to ease robot project setup. | Credit: Jacobi Robotics

Jacobi Robotics Inc. today came out of stealth with the launch of a new software product using artificial intelligence to improve the programming time and performance of robot applications. The Berkeley, Calif.-based startup also announced a partnership with Formic Technologies Inc.

Jacobi Robotics said it is building on breakthroughs from research labs at UC Berkeley and Carnegie Mellon University to provide tools to enable engineers to deploy robust solutions faster than existing tools. Conventional robotic systems take weeks or months to deploy, it said in a release.

Co-founder Yahav Avigal described Jacobi’s mission to The Robot Report: “Originally, the motivation was to make things faster and more efficient. But when we went to the industry, we saw how system integrators were working. We saw that it takes a very long time for startups to go from an idea to a deployed fleet of robots. We wanted to help shorten this cycle, and we realized that it’s not only about making the motions faster, but it’s [also] about automating the entire robot programming with our algorithms on the back end.”

Jacobi Robotics builds middleware on motion planning

Jacobi Robotics’ offering starts with motion-planning technology based on years of research in world-leading robotics institutions. Within the company‘s motion library, motion-planning primitives compute time-optimized, singularity-free, jerk-limited, and collision-free paths for robotic operations. The software connects directly to the robot controller via application programming interfaces (APIs).

Max Cao, co-founder and CEO of Jacobi, noted that there has been a revolution in the industry over the past decade, as vendors such as FANUC and ABB have opened up their APIs for deeper integration capabilities for robot control. He claimed that this is fundamental to the evolution of Jacobi’s middleware abstraction layer in the robotics control stack.

At press time, this was the list of supported robots, which Jacobi Robotics said it expects will grow over time:

| Manufacturer | Robot Model | Driver |

|---|---|---|

| ABB | IRB 1200-5/90 | ABBDriver |

| IRB 1300-7/1.4 | ABBDriver | |

| IRB 1600-6/1.2 | ABBDriver | |

| IRB 4600-60/205 | ABBDriver | |

| FANUC | LRMate 200iD/7L | |

| Franka | Panda | |

| Kinova | Gen3 7DoF | |

| KUKA | LBR iiwa 7 | |

| UFACTORY | xArm 7 | |

| Universal Robots | UR5e | UniversalDriver |

| UR10 | UniversalDriver | |

| UR10e | UniversalDriver | |

| Yaskawa | GP12 | |

| HC10 | ||

| HC20 |

Palletizing is an initial application

Palletizing and packing are the first two application areas that Jacobi Robotics is targeting. With the mantra “Robots should be configured, not programmed,” the company said its motion-planning software can provide robot-agnostic path planning and increase productivity by 20%.

Jacobi said it intends to help robot integrators reduce the project risk and the overall time that it takes to bring up a new robot workcell.

Palletizing is one of the most parametrically definable applications, which is why Jacobi is targeting it first. The application areas will expand as the solution matures, the company said.

Ken Goldberg, the William S. Floyd Jr. Distinguished Chair in Engineering at UC Berkeley and a Jacobi board member, spoke about generative AI’s impact on robotics at last year’s RoboBusiness event.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Jacobi partners with Formic to ease deployments

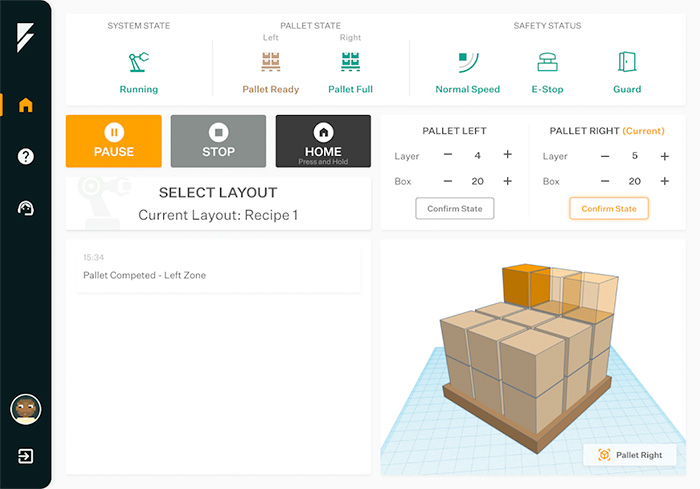

Jacobi Robotics has chosen to partner with Formic as it launches the Jacobi Studio product. Key to this relationship is the fact that the Formic platform is designed for simplifying palletizing and packing application deployments.

Formic is a robot-as-a-service (RaaS) offering, and the company has a large installed base of palletizing customers, with a backlog of systems to be deployed. The partners said addition of the Jacobi Studio to the Formic operating system will enhance the overall ease of use and capability of the combined system. It will also enable Formic application engineers to deliver systems faster to end customers.

The Jacobi-Formic alliance initially targets robotic palletizers that stack cases onto pallets for storage or shipment. More than $400 billion worth of U.S. trade is exported annually on pallets.

However, the physically demanding task of manual palletizing is a leading cause of worker’s compensation claims in the manufacturing sector. This challenge, coupled with a daunting labor shortage is driving growing demand and deployment of robotic palletizers.

“In an era where flexibility is not just an advantage but a necessity of robotics automation, the outdated tools for engineers are a bottleneck, impeding the rate of deployments,” said Cao. “Formic’s innovative robotics-as-a-service business model combined with Jacobi’s software platform is a game-changer and will empower system integrators and engineers to deploy with greater ease, flexibility, and scale. This partnership represents a fusion of business innovation and technology innovation. We are thrilled about the upcoming developments we have in store.”

The Formic Core operating system is designed to allow robots to be deployed, operated, and maintained more easily. | Credit: Formic

Tell Us What You Think!