|

Listen to this article

|

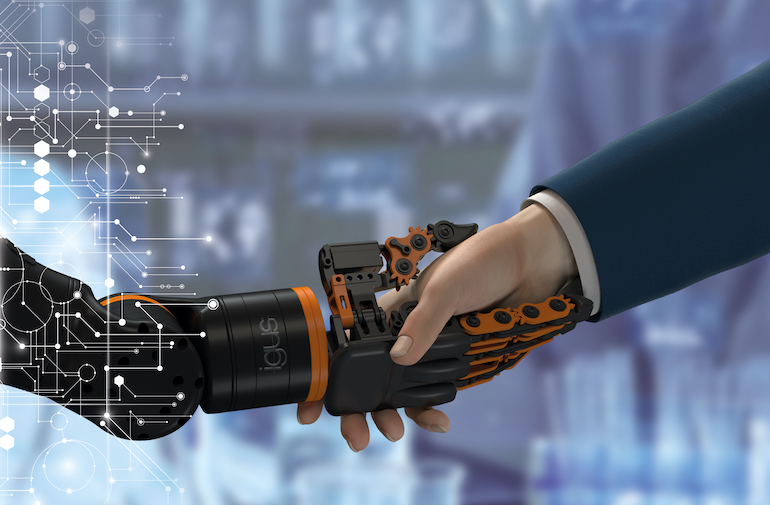

igus has developed a robotic hand for its ReBeL low-cost automation. Source: igus

igus GmbH has developed a finger gripper for its ReBeL collaborative robot. “The ReBeL can now perform a variety of simple humanoid tasks with the new low-cost robotic hand,” said the company.

Automation is entering small and midsize enterprises (SMEs), particularly in the form of collaborative robots or cobots. They can sort, pick and move items with the help of cameras, suction devices, and gripper systems.

The new gripper for the ReBeL cobot is made entirely of self-lubricating plastics and is designed to be cost-effective and easy to integrate, said Cologne, Germany-based igus.

“As the ReBeL is very light and inexpensive with a weight of around 8 kg [17.6 lb.] and a price starting at $6,899, it is often used in humanoid applications,” explained Alexander Mühlens, head of the low-cost automation business Unit at igus. “For this reason, we have received several customer requests for a robot hand that can be easily connected to the ReBeL via plug and play.”

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

igus gives ReBeL a hand for diverse tasks

The compact ReBeL provides a cost-effective way to start working with robotics, claimed igus. ReBeL stands for “Robotic Embedded-BLDC (brushless direct current motor) and electronics link.”

It is suitable for assembly, quality inspections, and tasks in the service sector, the company stated in a release. For these applications, igus offers a wide range of end effectors from various manufacturers on the RBTX.com marketplace.

“The ReBeL can take on a wide range of simple humanoid tasks and applications with the new low-cost hand,” said Mühlens. “We are thinking of such fields as research and development at universities, as well as tasks in the catering or entertainment industries.”

The ReBeL finger gripper is available for as little as $2,760, said igus. The robotic hand is compatible with all ReBeL models and is controlled via DIO (digital input/output) at the tool center point.

In addition, the new gripper can imitate a person’s hand movements, according to the company, whose U.S. headquarters are in Rumford, R.I. Last week, Top Workplaces named igus a top employer in Rhode Island.

High-performance plastics enable precise motion

igus said it directly provides all components of its finger gripper, including its flange, cables, and control unit. This guarantees 100% compatibility for ReBeL customers, it noted.

Self-lubricating high-performance plastics help keep the price low, asserted igus. Not only are plain bearings in the joints made of iglide polymers to be cost-effective and self-lubricating, but they also ensure smooth and precise movements of the individual fingers, it said.

Extensive tests in the company’s 3,800-sq.-m (40,902.8-sq.-ft.) laboratory has proved the longevity of the humanoid hand. They are intended to be flexible and can be controlled via various interfaces, including USB, TTL (5V) serial, and internal scripting.

Beyond the finger gripper, igus offers other products for the ReBeL platform. These include, for example, fire-resistant smoke hoods, a seventh axis, gripper sets, adapter plate sets, power supplies, a finished workstation, and connection cables.

The company recently said its igusGO mobile app can enhance machine optimization using maintenance-free plastics for more than 450 industrial applications.

Tell Us What You Think!