|

Listen to this article

|

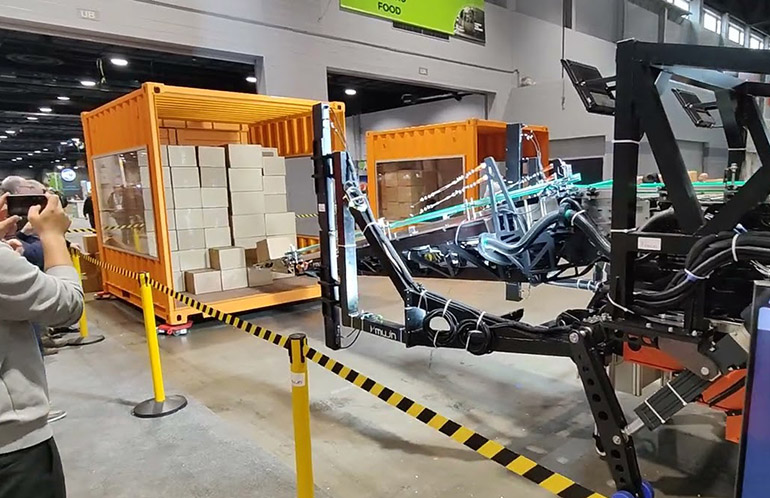

Mujin TruckBot uses MujinController technology to unload trailers, as seen here at Automate 2023. Source: Mujin

Mujin Inc. today announced that it has finalized its Series C extension round with an additional $18 million, bringing its total Series C funding to $104 million. The Tokyo, Japan-based company said it plans to use the funding to advance the accessibility of its MujinController platform for robotics integrators and end users.

“It has been quite a roller coaster ride,” Ross Diankov, CEO of Mujin US, told The Robot Report. “From the beginning, our [trade show] booths attracted attention. It wasn’t just sensors, vision, or motion planning; we’re trying to bridge the gap of these disparate technologies for a coherent system, which culminated in our MujinController, the first intelligent robot controller on the market.”

Founded in 2011, Mujin said in a release that it “works with many of the world’s largest companies to make material handling applications easier to deploy, more accurate, and less costly.” The company has designed its controllers as a common platform for industrial and collaborative robots for pick-and-place and other logistics applications.

“When you look at robotics as a whole, no single company stands out because of its interdisciplinary nature,” Diankov said. “It requires a lot of effort to unify technologies, which is exactly the challenge we tackled.”

MujinController starts with digital twins

The MujinController uses “machine intelligence” and “real-time digital twins” to enable robots to operate autonomously and reliably in production, said Mujin. The company claimed that its approach can help developers improve automation precision and safety for existing and new applications.

“It’s a real paradigm shift — we do not teach by demonstration,” Diankov said. “We infuse the robot with a digital twin to understand its surroundings, and only then do we do motion planning. Previously, one had to program deterministic waypoints for robots.”

What does “real-time” mean?

“Every millisecond, in regular and predictable intervals, MujinController gathers data from all pipelines,” replied Diankov. “Once we have the state of the environment, the robot can simulate into the future and plan many moves ahead to find the optimal path.”

But what if the robot’s state itself changes?

“If some exception happens, or even if the power goes off, then the robot has to recover itself for safety,” said Diankov. “It’s a pretty big thing that many in automation struggle with. Things will always happen on the line. How to recover easily — that’s where non-volatility comes in, like RAM on a computer. NVRAM survives shutdowns.”

Machine intelligence a step to full autonomy, says Mujin

“Machine intelligence is the combination of the digital twin, real-time control, motion planning, and perception,” Diankov continued. “These four components allow a machine to reason about its surroundings in a predictable way and to complete tasks in an optimal way.”

“Then, robots can do extremely advanced tasks that were previously impossible to program,” he said. “This is the concept that glues together intelligent controls and robotics. It’s also the technology needed to get to true autonomy — many autonomous vehicle companies are actually building these digital twins internally themselves.”

Diankov asserted that machine intelligence can help accelerate robotics development and commercialization.

“Robotics users can’t trust demonstrations. The only way is to prove robots in the real world, which is what Mujin does,” he said. “We help shorten the time from concept to working in the field, which determines how fast robotics grows.”

“We’re observing right now that, even with an inexperienced team or a new integrator, the time to create a new behavior or deploy a new system is decreasing exponentially,” Diankov said.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

TruckBot and QuickBot tackle common logistics pain points

“It’s really about listening to the pain points of our customers every single day,” said Diankov. “The technology is still maturing, but even if customers run into an unexpected problem, they can be confident that Mujin is there to solve it with them.”

“We can build systems extremely fast, like the TruckBot for trailer and container unloading,” he added. “Under the hood, it’s all MujinController. It’s different hardware than other robots but the same concepts internally.”

In addition to the MujinController and TruckBot, Mujin offers QuickBot for depalletizing.

“All applications are in demand right now, but there are not many automated systems that can do mixed-SKU palletizing or truck unloading, which are especially important in logistics, to singulate freight to sorter systems,” said Diankov. “When we choose applications to use with our controllers, we’re not trying to reinvent the wheel.”

Mujin expands strategically

Mujin said its Series C funding brings its cumulative fundraising to $178 million. Japan Post Capital Co. and another strategic partner provided the capital boost for the extension round. Mujin and Japan Post said they plan to innovate to improve efficiency for Japan Post’s facilities.

How did the company manage to get funding in a time of restrained venture capital?

“Mujin is in a unique position — we started in Japan and learned what it takes to build reliable robotics,” Diankov recalled. “We then expanded our manufacturing arm to China. We work with talented people who understand manufacturing and have incredible hardware.”

The global market for robot controllers could experience a compound annual growth rate (CAGR) of 14.8%, from $6.3 billion in 2023 to $12.5 billion by 2028, according to Markets and Markets. It cited increasing collaboration between robot makers and software providers, as well as demand for industrial automation in the logistics, automotive, and electronics markets, among others.

The company last week opened an office in Eindhoven, Netherlands. In the U.S., Mujin has been growing its team in Atlanta after opening an office in the area in 2021.

It considered Boston for its research-and-development talent and Pittsburgh for its proximity to automotive manufacturing, but it chose Atlanta because of its logistics end users such as UPS and materials handling integrators, including Vanderlande, FORTNA (including the former MHS), and Geek+.

“We want to be close to customers,” said Diankov. “Deployment is the best metric of success for investors. When you ask about ease of use and deployments, many robotics providers say they’re still working on it.”

“Our first task is to deploy systems and build trust,” he noted. “After we’ve achieved that, we’ll figure out how to deliver the platform and put it into people’s hands to create their own applications. A lot of the Series C money is going into creating SDKs [software development kits] and user interfaces so we can start selling MujinController to the masses.”

Tell Us What You Think!