|

Listen to this article

|

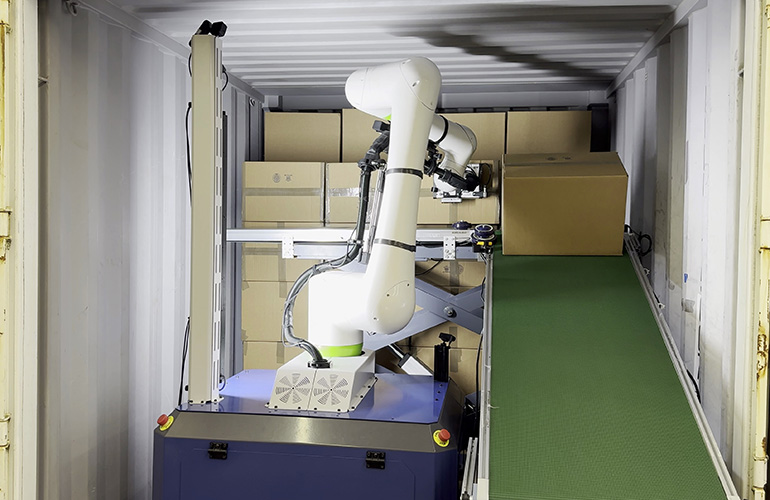

Anyware Robotics today announced an add-on for its Pixmo robot for truck and container unloading. The patent-pending accessory includes a vertical lift with a conveyor belt that is attached to Pixmo between the robot and the boxes to be unloaded.

Every year, an estimated 28 million containers enter the U.S. with boxes that need to be unloaded, noted Anyware Robotics. The Fremont, Calif.-based company said its robots can autonomously unload boxes in containers and trucks more safely, cost-effectively, reliably, and quickly than humans can.

The integrated Pixmo software quickly processes the various heights of the boxes in the container and then controls the conveyor of the add-on to move up and down to these positions to “meet” the robot arm as it unloads, Anyware Robotics explained. The add-on is designed to enhance the robot’s unloading efficiency, weight capability, and reliability at marginal additional cost, it said.

Pixmo no longer has to “rotate and place” to a conveyor but simply “pulls” to a conveyor,” said Anyware in a release. This minimizes the distance the robot arm needs to travel to unload each box.

The change in motion doubles the throughput of Pixmo to up to 1,000 boxes per hour, and the support of the conveyor increases the weight capacity of the solution to a 65 lb. (30 kg), the company said.

Anyware designs for varied logistics facilities

Anyware Robotics emerged from stealth and launched Pixmo last month. It said the robots are suitable for unloading at transload facilities, cross docks, third-party logistics providers (3PLs), distribution centers, and e-commerce fulfillment warehouses. The company asserted that its robots can be installed within days to enhance operational efficiencies and predictability.

Pixmo combines an autonomous mobile robot (AMR) base, a FANUC collaborative robot arm with six degrees of freedom, and a vacuum-powered end effector designed for case handling. It does not require costly software integrations or infrastructure changes to be deployed into the warehouse environment, said Anyware.

With a mobile base that has the footprint of a warehouse pallet, Pixmo can move in any direction to create the best handling pose for its cobot arm, both in and outside the container, added the company. Pixmo is built on a software stack that combines the latest perception algorithms, learning-based motion planning, and a state-of-the-art data generation pipeline for AI training, it said.

While Anyware Robotics is focused on meeting current demand for truck unloading, it noted that Pixmo’s flexible design and over-the-air software updates could enable it to be used for other warehouse tasks. These include palletizing, depalletizing, case picking, and container loading, which would further accelerate the robots’ return on investment (ROI).

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Pixmo to be shown, available soon

Anyware Robotics plan to publicly demonstrate its Pixmo robot, as well as a prototype of the new add-on, for the first time at Booth A11227 at MODEX 2024.

“We are excited to showcase our Pixmo robotic solution and the innovative patent-pending add-on for unloading at MODEX,” stated Thomas Tang, co-founder and CEO of Anyware Robotics. “The versatile Pixmo can easily connect to, power, and enable add-ons for different applications. This is all part of our plan to help it deliver increasing capabilities for different warehouse applications in the future.”

The commercial version of Pixmo is scheduled to be available in the summer of 2024. It will be available via direct-purchase or robots-as-a-service (RaaS) models to allow users to scale deployments as their business grows. The add-on is scheduled to be available in the third quarter of 2024.

Companies that are interested in participating in a Pixmo pilot program or meeting with a Pixmo executive at MODEX can contact Anyware Robotics via its website.

Anyware will soon offer an add-on for its Pixmo truck-unloading system. Source: Anyware Robotics

Tell Us What You Think!